NEW: Suppliers Guide To Aviation RFID

A Suppliers Guide to Aviation RFID

This is an excerpt from a (10-page) summary guide to Aviation RFID and Barcode Part Marking, covering the ATA Spec2000 part marking standard, pertinent FAA documents supporting RFID on aircraft, examples and available vendors who can help you with a successful implementation. It also includes key points from the IATA document describing the Airline Business Requirements for RFID which is important to know what the airline customer wants. This is an educational overview of what a supplier needs to do to meet technical and customer needs.

Overview:

-

Purpose – The purpose of this document is to provide suppliers an overview of aviation part marking using barcodes and RFID and how to implement it correctly to meet their own needs and customer’s needs. These are the summary and views of what is important to know but is not exhaustive – reading the referenced material would be necessary for a full understanding.

-

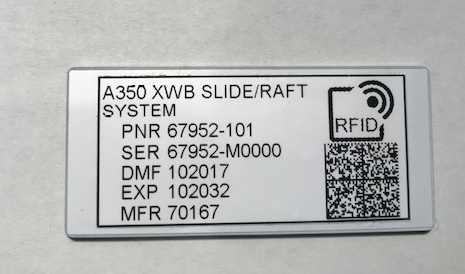

Barcode Birth Record data on parts/labels/data plates is a minimum requirement for the airlines. If your part is the type that airlines want to read quickly from a distance (e.g., most emergency equipment) they also want it to have an RFID tag. The RFID tag typically carries the 2D barcode and the human readable data, if space is available on the face of the tag.

-

Key requirements discussed:

o Spec2000 has defined data structure – follow it exactly!

o Serialized parts – there are two ways to serialize your parts:-

Unique serial number within your CAGE Code (Construct 1), and

-

Unique sequence number within part number within your CAGE Code

(Construct 2).

-

These are different and needed for cradle-to-grave traceabililty of the part. Spec2000 data requires that you specify which one you are using – understand how you uniquely ID your parts via Construct 1 or 2!

-

-

Brief History – the aviation industry has had a part marking specification since 1990. Usage of RFID part marking began in 2002 when Boeing had their first meeting with the FAA to discuss how they could go forward with using this technology safely and effectively. Within the ATA organization the standard started being developed in the 2003-2005 time frame with the first publication of ATA Spec2000 Chapter 9-5 RFID in 2006. In 2004, the ATA applied to the EPC Global organization to be assigned our own identifier number on RFID tags which would separate our needs, our data structure, and our process from other industries like retail, medical, logistics and agriculture. Because of the radical new approach we were taking with this standard UHF RFID technology it took 5 years to be approved by the international GS1 organization. (continued...)

- (click here to get to the full guide)

---

More bar code and RFID news and competitive intelligence from the last week: (use the Subscribe button on the left menu to be sure you don't miss anything important. Once a week or once a month. No spam, ever!)

- Reverse Logistics Workflow Added to Smartphone App

- Acuity Joins Honeywell Partner Program - Adds Scanning, Printing and Mobile Computing Solutions

- Inventory Pro Online Adds Integration With WooCommerce

- RFID Solutions Bring Clear Sightline Into $1.2 Trillion Shrink Problem

- Avery Dennison to Acquire Smartrac’s RFID Inlay Business

- Supply Dynamics Named National Champion in US Air Force Sponsored Microelectronics Supply Chain Provenance Challenge

- Metalcraft Launches RFID Company To Support Small Businesses

- Health Traceability Company Raises 30 Million Euros From Funds Managed by Xerys

- Socket Mobile Updates Capture SDK for iOS 13 Compatibility

- Lightning Labels to Have a Big Presence at the Private Label Expo in Chicago

- Secure and Productive In The Supply Chain With Identify3D and EOS

- Barcode Scanner Market Procurement Intelligence Report

- Digimarc Brings Scan & Shop Technology to Walmart's Toy Catalog

- Millennials Abandon In-Store Purchases When Items Are Out-of-Stock: Zebra Study

- ScanSource Announces First Quarter Results

- ScanSource, Inc. Names New Board Member

- A New Chapter in Diamond Supply Chain Management

- Logistyx Technologies Named #1 Fulfillment Software Provider to Internet Retailer’s Top 1000 Retailers

- Scandit Integrates With Epic Rover to Enable Accurate Native iOS Camera Scanning in Healthcare

- Impinj Reports Third Quarter 2019 Financial Results

- SpotSee Launches ShockWatch RFID for Tracking Damage Through Supply Chain

- 20.1 Billion RFID Tags to Be Sold in 2019, Finds IDTechEx Research