The Future is in Color: On Demand Color Barcode Labeling

Color labeling helps companies stay compliant, create visual appeal, organize products and processes

We live in a world of color. Marketing research indicates that over 80% of visual information is related to color. However, black and white barcode labeling has largely remained an industry standard for many reasons: pre-printed color labels can be inefficient and expensive; because color label templates are pre-printed, it is difficult to change variable information on-demand; regulatory compliance has not traditionally required color. However, advances in labeling software, warehousing efficiencies, inventory selection improvement and regulatory requirements are leading almost all industries toward a future in color labels.

Benefits of Color Labeling

Incorporating color onto your barcode labels offers the ability to create a visually appealing design that is also highly functional, providing operational benefits while also conveying information such as:

-

- Branding

- Marketing & promotions

- Product identification

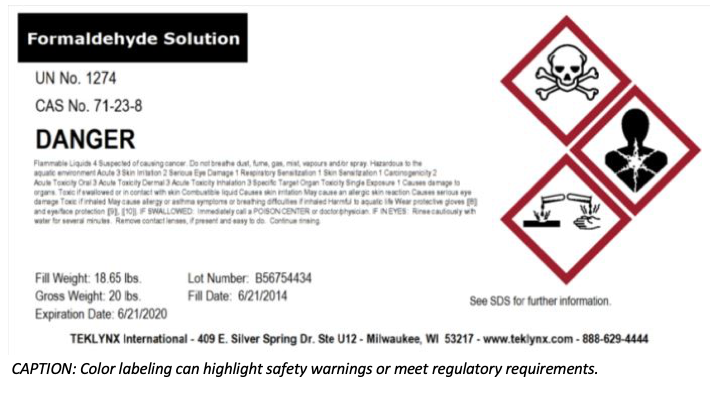

Color Helps Communicate Safety Warnings and Meet Regulatory Requirements

Color labels can help provide additional levels of communication by enabling the addition of bold safety warnings to catch attention and drawing the eye to critical information. An increase in industry standards and government regulations that specifically require the use of color has made this issue more prominent for many manufacturers, in particular food manufacturers, pharmaceutical and chemical manufacturers, and the newly-emerging Cannabis industry. Global Harmonized System of Classification and Labeling of Chemicals Regulation (GHS), Cannabis labeling, and The US Food Allergen Labeling & Consumer Protection Act (FALCPA) are just some of the regulations that have color labeling requirements.

Warehouse and Product Efficiencies Through Color

Required or by choice, color labeling increases safety and efficiency. Using color as part of your identification process helps to make items in a warehouse easily recognizable by the human eye, resulting in quick object recognition. It can also assign meaning to products and make product identification easier, like how red means stop and green means go.

Color is a huge advantage when it comes to efficiency and accuracy in general. For any company with several different production lines, products may have a similar shape and size, or use similar components. Color coding of labels offers a simple, reliable solution.

On Demand Color Labeling Increases Efficiency, Reduces Cost and Waste

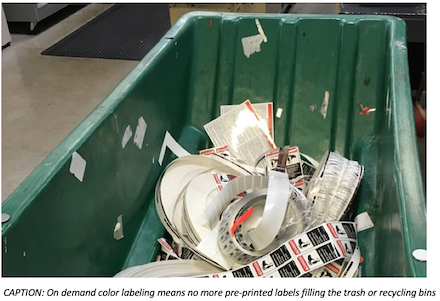

On demand color labeling allows label designers to create a smart label template that incorporates variable data & images, so you can design and print labels as you need them. There is no more need to order and store pre-printed label stock that may be outdated as labeling data changes. On demand labeling reduces the risk of errors due to print misalignment that happens when you use pre-printed stock. Epson's line of ColorWorks label printers work seamlessly with TEKLYNX native printer drivers that enables true WYSIWYG (What You See Is What You Get) on-demand color label printing.

Epson is the first to launch printers specifically designed as a color upgrade to black-only thermal transfer printers.1 The new ColorWorks models deliver on-demand, 4- or 8-inch wide color labels with 1200 dpi resolution at a comparable price to thermal options. Engineered for mission-critical applications, the reliable printers speed through labels at up to 5-inches per second. TEKLYNX CODESOFT label design software makes it easy to add high resolution artwork to labels while combining dynamic serialization, data and barcodes.

With TEKLYNX CODESOFT barcode label design software solution, manufacturers are able to:

-

- Speed up label design and print times

- Increase accuracy so what is seen on screen is what gets printed

- Have CMYK and RGB color matching at design and time of print

- Eliminate the waste and save the storage space of pre-printed labels

- Maintain brand consistency

- Meet complex customer requirements

- Maintain regulatory compliance while increasing safety

- Create eye-catching and attractive labels

- Control and optimize print output

Should you make the switch?

These are the things to consider when looking at making a switch from black and white barcode labeling to on demand color labeling:

-

- Do you have a high volume of print-time variables on your barcode labels?

- Do those labeling and/or product variables change regularly?

- Does your industry require use of color in labeling for compliance, regulatory or safety reasons?

- Would use of color labeling give your company a competitive advantage from a marketing standpoint?

- Do you feel that warehouse and process efficiency would improve if labels made use color-coding?

- Are you tired of wasting pre-printed color label stock?

- Do you experience delays in production due to misalignment on over printing?

If you answered “yes” to any of these questions, it is time to put the color in your barcode labeling future.

By Nick Recht

Enterprise Product Manager

Nick Recht has partnered with organizations throughout the pharmaceutical and medical device industry, and beyond, to make labeling operations more efficient and accurate while meeting stringent regulations and requirements. Recht specializes in designing enterprise-level labeling software solutions that integrate into existing ERP systems resulting in wide-scale operational and labeling improvements for the companies with which he partners. He is well known throughout the industry for his innovative approach to enterprise labeling software solutions and relentless pursuit of operational excellence. He can be reached at

Other articles on labeling: