Gerber Facilitates On-Demand Textile Supply Chain - Showcases Micro Factory with Digital Printing

TOLLAND, Conn., June 7, 2018 /PRNewswire/ -- Increasingly in an on-demand world, consumers expect personalization and immediate delivery when they see what they want. To remain competitive, brands and manufacturers are being compelled to re-examine their processes and find ways to become more agile and remain relevant in a time of ever-changing consumer trends. "We have been investing in and developing technology to help our customers transform and connect their workflows to meet the needs of an on-demand world, enabling a seamless digital print and automated cutting workflow to work with leaders in digital textile printing," said Scott Schinlever, president and COO Automation Solutions at Gerber Technology. "Recently we showcased Gerber's textile workflow and automated cutting in a variety of micro factories with Kornit, EFI™ Reggiani and Mimaki. The strong growth trend in digital textile printing can be accelerated by Gerber's integrated eco-system of software and automated cutting systems, delivering value through connectivity and achieving Industry 4.0 expectations from concept to finished product."

Over the last two weeks, Gerber participated in two global industry events, FESPA in Berlin and Texprocess Americas in Atlanta. At the shows, they demonstrated on-demand manufacturing applications that included their Digital Solutions, integrating data from design to finished product leveraging YuniquePLM® and the AccuMark® Platform, digital printing technologies from three industry leaders, Gerber's Z1 single-ply cutter with ContourVision™ automated scan-to-cut system and both robotic and lean loop sewing operations.

Digitalization and the adoption of Industry 4.0 principles are empowering purchase activated, on-demand manufacturing. Brands and manufacturers are able to respond to demand versus producing to supply. The approach eliminates costly inventory and re-defines just-in-time manufacturing, so production adjusts as demands fluctuate – allowing products to be produced more efficiently and sold at full retail price without heavy discounting.

The Gerber team is passionate about supporting our customers and their needs as the industry changes. "We are empowering our customers to turn their data into speed, helping them be more agile and get their products to market. We back it up with best in class aftermarket support to ensure maximum productivity and lowest total cost of ownership in the industry," stated Schinlever. "We look forward to continuing to partner with key players in the industry to help our customers compete and win."

About Gerber's Digital Solutions

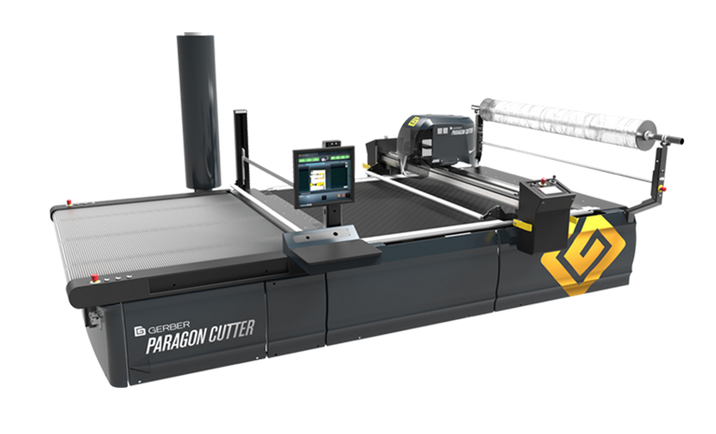

Gerber's Digital Solutions include the newest releases of YuniquePLM product lifecycle management software, as well as AccuMark, the industry-leading pattern design, grading, marker making and production planning software, AccuMark 3D and AccuPlan™. The Digital Solutions architecture incorporates the tenets of Industry 4.0 and uses common file structures. Data can easily be passed to the cut room where smart machines, like the GERBERspreader™ XLs Series and the Gerber Paragon® line of multi-ply GERBERcutters, can process the order with a simple barcode scan. Closed-loop, end-to-end Digital Solutions like Gerber's integrates software and smart machines, allows companies to automate their entire process and streamline data and workflow necessary to provide insight, maximize throughput, minimize errors and reduce labor costs to be competitive in mass production environments.

About Gerber Technology

Gerber Technology delivers industry-leading software and automation solutions that help apparel and industrial customers improve their manufacturing and design processes and more effectively manage and connect the supply chain, from product development and production to retail and the end customer. Gerber serves 78,000 customers in 134 countries, including more than 100 Fortune 500 companies in apparel & accessories, home and leisure, transportation, packaging and sign & graphics. The company develops and manufactures its products from various locations in the United States and Canada and has additional manufacturing capabilities in China.

Based in Connecticut in the USA, Gerber Technology is owned by AIP, a New York based, global private equity firm specializing in the technology sector and has more than $3.0 billion assets under management. Visit www.gerbertechnology.com

--

More news:

- Skin Wearable NFC Disc Delivers a Stunning Performance at iHeartRadio’s Wango Tango

- Starbucks Adds Punishment To Loyalty Program

- Children’s Hospital Colorado Contracts with Mediware® Software for Blood Supply Chain Software

- EPAY Systems Delivers New RFID Slim Time Clock

- EnterWorks® Partners with Label Insight for ‘Big Data on Big Food’

- META Storage Solutions Inc. and The Numina Group Partner to Provide Neuco’s Next Generation Warehouse Distribution Center

- ALL-TAG Announces Release of Q-Tag® Tag

The Bar Code News is now in its 9th year and is pleased to bring you great exclusive content. We rely on sponsors to keep this website running, so please let vendors know that you've seen them here. Thank you. Is your bar code related business listed in our free directory? Over 500,000 visitors a year come to Barcode.com. It pays to be here.