Alert: Update Barcode Verifier Software Now

by John Nachtrieb, barcode-test.com

After many months of technical committee deliberations, the ISO committee has released an update to the ISO 15416 Standard. This impacts how 1D barcode verifiers calculate and report grading.

The importance of the update derives from the importance of this ISO specification. It’s all about managing the potential risk associated with barcodes that don’t perform as expected because of low quality. A brief review underscores why this is important.

Although barcode scanners also must comply with a similar performance standard—ISO15426-1 for 1D barcodes and ISO 15426-2 for 2D symbols—the several attributes to which scanners should comply have a tolerance. They will not all perform identically. Furthermore, scanners have evolved in several ways. Initially, in the days of linear-only barcodes, scanners were all laser-based. Then came linear CCD arrays, and most recently, camera-based digital scanners. This evolution also brought changes in decode algorithms, the mathematics behind how the reflective differences in the barcode images that encode the barcode data are interpreted.

Therefore, in the real world, you not only have barcodes of various levels of print quality circulating through supply chains and point-of-sale systems, you also have scanners of varying degrees of accuracy and aggressiveness attempting to read them. That is why ISO compliance barcode verification is so vital—and why a change to the verification standard is so important.

The recent update to ISO 15416 changes the way grading is calculated and reporting for the following parameters:

- Symbol Contrast (SC)

- Modulation (MOD)

- Decodability

- Defect

These are the “graded” parameters that contribute to the scan grade of a barcode. In other words, these parameters could product a grade of 0.0 (ANSI F) or 4.0 (ANSI A) or anything in between. There are also non-graded or Pass/Fail parameters that are not affected by this spec change.

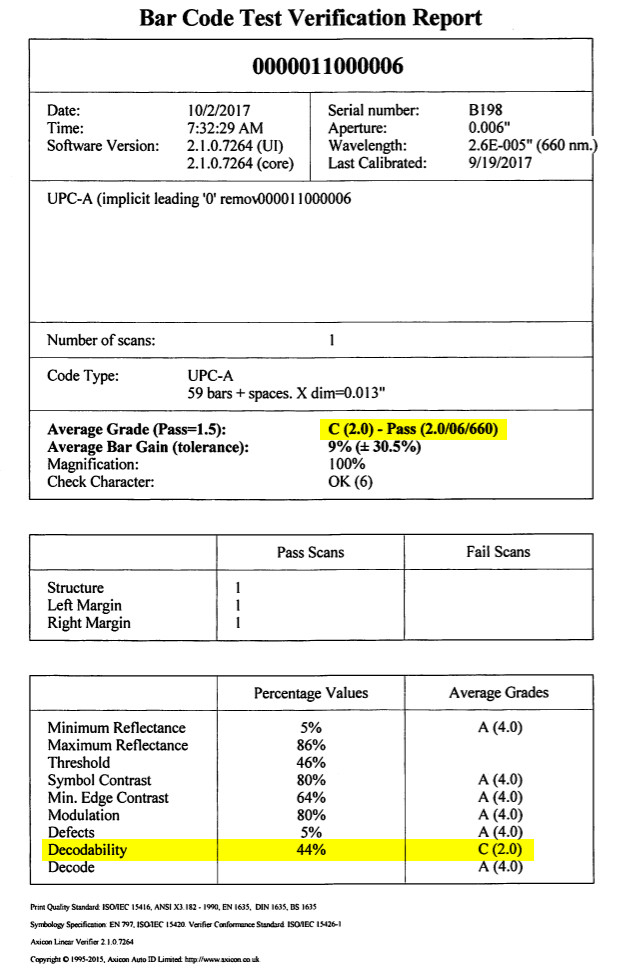

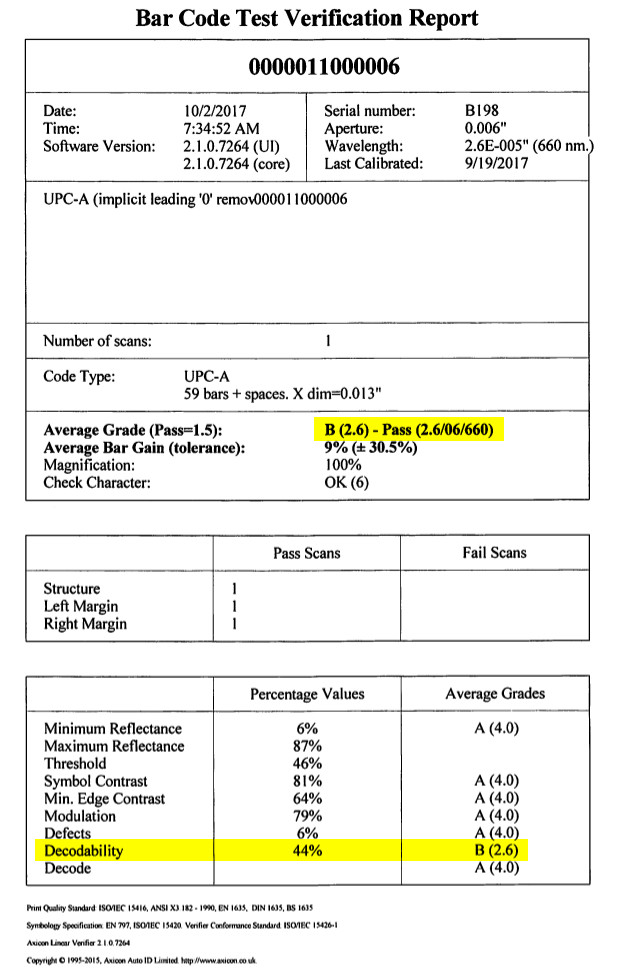

Up until the recent update, the grading of the graded parameters was measured only to the lowest whole-number and its equivalent lowest ANSI letter. For example, in the old grading system, an ISO score of 2.6 for Decodability would have been rounded down to 2.0 and reported as an ANSI C. The update requires fractional (first decimal place) grading, and the 2.6 ISO score will now be reported as an ANSI B.

At first look, it seems that the update will produce consistently higher grades, and that is not necessarily true. When doing ISO- recommended 10 scan averaging the final grade could be above or below the numerical threshold for the higher or lower letter grade. What the ISO specification update really emphasizes is the importance of paying attention to the ISO numerical grade. Only this can tell you if the C grade is a high C (approaching a B), a solid middle-of-the-road C or a low C (approaching a D).

This might seem like a hair-splitting exercise, but remember, the whole point of barcode verification is predicting barcode performance in a world of inconsistent scanner behavior and latent barcode-related liability. Fractional grading makes it easier to see subtle barcode grade migrations during a print run and to anticipate problems before they actually occur. Fractional grading makes barcode verification more accurate—and that could be an important factor in differentiating whether an apparently bad barcode is really the fault of the barcode itself or the scanner.

For those of us concerned with ISO 15415 for 2D symbols such as QR Code and Data Matrix, whole number grading will continue into the foreseeable future. A fractional grading update is not yet on the agenda, although grading is currently reported to one decimal point. Fractional grading is less of an issue with matrix codes since only one scan is taken—the ISO-recommended 10 scan protocol is not an issue with 2D symbologies.

Old whole number report:

New whole number report:

---

Other Barcode news of interest: