Understanding and Implementing Enterprise Barcode Label Management

By: Doug Niemeyer, TEKLYNX Americas

Today, more than ever, companies of all sizes are looking to technology providers and partners to help them meet stringent label requirements and compliance standards while increasing operational efficiency. What many companies don’t realize is that this can be achieved by simplifying their labeling process with enterprise label management (ELM) solutions.

Today, more than ever, companies of all sizes are looking to technology providers and partners to help them meet stringent label requirements and compliance standards while increasing operational efficiency. What many companies don’t realize is that this can be achieved by simplifying their labeling process with enterprise label management (ELM) solutions.

Successful ELM implementations require companies to shift their labeling mindset, viewing labeling as a strategic process as opposed to a tactical one. With ELM, companies centralize label management by integrating labeling into their broader business systems. This alone is pivotal to driving a company’s overall operational efficiency because it saves time while reducing errors and IT overhead.

Making the mindset shift from tactical to strategic can seem daunting, but at TEKLYNX we’ve learned that companies who begin with information around the basics of ELM, ELM benefits, implementation expectations, as well as what to expect in the future, position themselves to realize the benefits of ELM both in the short and long term.

ELM Basics

The simplest way to define the basics of ELM is to address five simple questions: what, why, who, when and where. “The Big Five”, as TEKLYNX has defined it, helps companies better understand ELM and its benefits.

What is ELM?

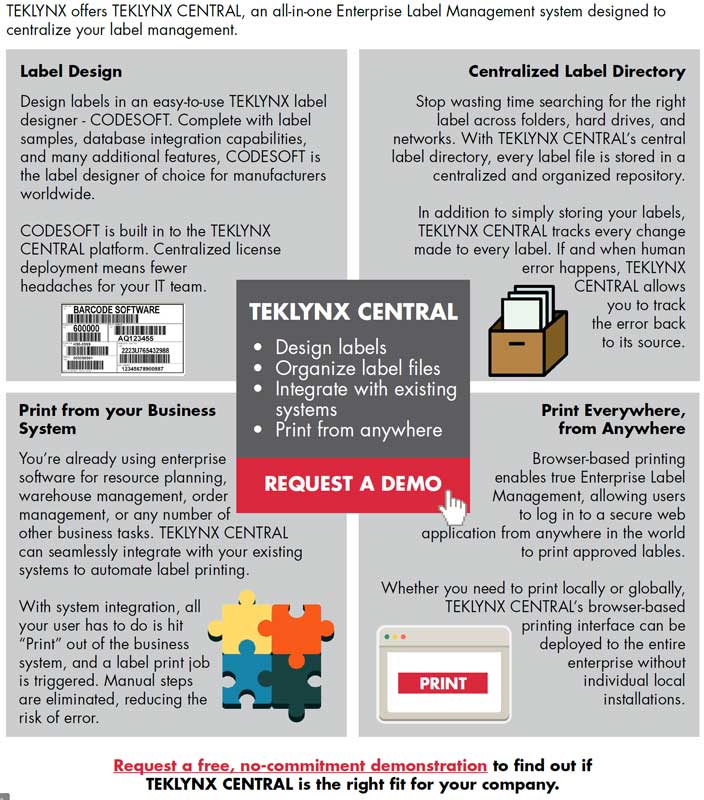

ELM is made up of four primary components: 1. the ability to create and print barcode labels used for shipping, inventory, products, and more; 2. label approval, traceability, security, storage, and version control for all labels created and printed; 3. print automation to remove manual operations from the process; 4. a browser-based print interface for seamless and secure label printing locally and around the globe.

Why do businesses consider ELM?

Any form of automation can save a company money, and label printing is no exception – integrating labeling with a business system saves time and reduces errors. The centralization of label management offers many operational efficiencies while the browser-based printing interface eliminates the need for many local software installations, reducing IT overhead.

Who is the right fit for ELM?

Any company looking to consolidate, standardize, and/or centralize label management, regardless if in one location or across a global operation. Often, these companies are looking to reduce manual steps throughout the label lifecycle, meet stringent label requirements or compliance standards, and improve IT management and operational excellence.

When is the right time to consider ELM?

Four common triggers for considering ELM include: 1. lean initiatives; 2. government regulations/initiatives in labeling or process management; 3. internal initiatives to improve efficiency, reduce errors, or create more control; 4. business growth, acquisition, or expansion.

Where should a company start?

By taking the time to truly understand the benefits of ELM as they pertain to a specific company’s needs. Start with the end state in mind and look to technology providers that have both resources and the customer service necessary to help.

ELM Benefits

After a company is able to truly understand ELM, it begins to see how it can drive efficiency across its processes. Successful implementation can have a cascade effect, meaning companies can realize benefits like error reduction, time savings, and cost savings across a variety of processes. For example, integrating label printing into an existing business system takes manual steps out of the process, saving time and reducing errors. And, because integration enables automation, print speed increases while mistakes decrease.

Another efficiency exists within the ELM software solution itself because it includes built-in approval rules for label design and printing. These rules streamline processes, further reducing misprints and errors. All while centralized IT management means the end of managing individual local installs, saving additional time.

ELM Implementation

Gaining a true understanding of the ELM implementation process is as critical as understanding the basics and benefits of ELM.

Implementation is a process, and processes take time. The average timeline to implement and ELM solutions is three to four months, but this process can be lessened or lengthened dependent upon levels of approval needed to get started, staff availability, and the ability to change the company’s current process.

And it’s not just the timeline that varies when it comes to implementation, the actions that make up the implementation process vary as well. Leveraging decades of experience, TEKLYNX created a general outline of the ELM implementation process. Although this process varies from company to company, the outline has proven helpful as it provides companies with a general understanding of what they’ll encounter. The “Eight Steps to ELM Implementation” include:

- Discovery: Define labeling environment’s current state and desired future state

- Proposal: Develop a Customer Requirement Document (CRD) and propose a solution

- Kick off: Company and technology solutions providers partner

- Preparation: Prepare and install the server

- Configuration: Configure the server and begin initial testing

- Label Design: Complete label design work and complete solution training (including label design, approval, printing, management, admin, reporting) on label design software

- Training: Train staff on the ELM solution

- Roll out: Take a phased approach to roll out, one step at a time

Future of ELM

When an ELM implementation occurs, a variety of departments should be involved in the process. At minimum, this usually includes IT, Quality Assurance and Production. Given that IT maintains the system, Quality Assurance is responsible for complying with mandates and regulations, and Production becomes the main user, it’s critical that these departments continue to work together beyond implementation. Strong communication among departments can help ensure the ELM system stands the test of time.

In addition to understanding the important role a company’s departments play in the continued success of an ELM system, it’s also important that a company truly understands its ELM technology solution provider. This means an understanding beyond product – a company should be looking for a partner, not just a technology solution. This is critical to an ELM system’s future as a good partner should provide unmatched customer support along with effective technology solutions.

Information is king

Knowledge is power, but when it comes to ELM, information is king. Gathering information before implementation is critical as it helps companies look beyond a quick technology solution purchase to understanding the importance of a customer support-focused technology partner and a productive implementation process. Learn more about ELM with TEKLYNX’ Answering Your Questions about Enterprise Label Management eBook.

---

About the Author

Doug Niemeyer, TEKLYNX Americas General Manager, is responsible for the success of TEKLYNX Americas’ business, its employees and resellers, while spearheading ongoing development of industry-leading solutions to help customers successfully run their businesses.

Doug Niemeyer, TEKLYNX Americas General Manager, is responsible for the success of TEKLYNX Americas’ business, its employees and resellers, while spearheading ongoing development of industry-leading solutions to help customers successfully run their businesses.

TEKLYNX Americas is a division of TEKLYNX International SAS, a fast-growing organization with barcode label design software implementations in more than 75 percent of Fortune 500 companies throughout the world such as Nestle, Kraft Foods, Owens Corning, Rockwell Automation and Johnson Controls. Under Doug Niemeyer’s leadership as General Manager, TEKLYNX has extended its reach in the enterprise market as a global leader in barcode labeling software and a provider of solutions designed to help businesses increase efficiency and streamline operations while minimizing costs and mitigating risk due to manual process errors. Doug can be contacted at:

---

Other Barcode news of interest: