Manufacturing and Food Traceability With Blockchain and Mobile Technologies

BOISE, ID -- SEPTEMBER 26, 2019 --

Still using notepad or a spreadsheet to keep track of lots and batches? Congratulations! You loose money daily on the extra effort. You lose opportunities by not being able to bid on attractive projects. And if you are in a food industry, congratulations again! You are in violation of the Title 9, Chapter III, Subchapter E, Part 417, Paragraph 417.4 of the Code Of Federal Regulations that requires you to create, validate and maintain Hazard Analysis and Critical Control Points (HACCP) plans, record and keep records of relevant lot and batch data. Lot traceability is not a “nice to have” option; it is a requirement for manufacturers, food and beverage manufacturers, food preparation, food service and produce companies.

Still using notepad or a spreadsheet to keep track of lots and batches? Congratulations! You loose money daily on the extra effort. You lose opportunities by not being able to bid on attractive projects. And if you are in a food industry, congratulations again! You are in violation of the Title 9, Chapter III, Subchapter E, Part 417, Paragraph 417.4 of the Code Of Federal Regulations that requires you to create, validate and maintain Hazard Analysis and Critical Control Points (HACCP) plans, record and keep records of relevant lot and batch data. Lot traceability is not a “nice to have” option; it is a requirement for manufacturers, food and beverage manufacturers, food preparation, food service and produce companies.

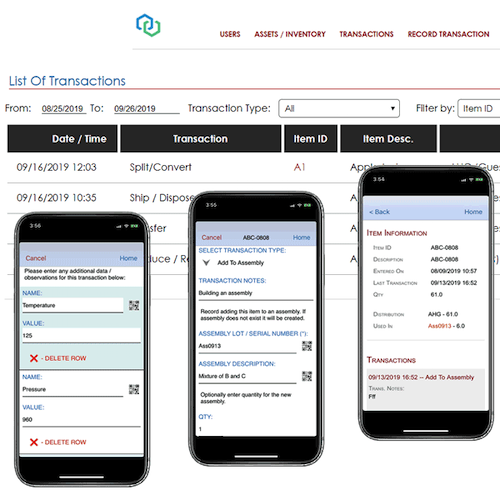

You already know that, right? What you don’t know is that you do not need to be a large corporation with deep pockets to be able to afford necessary HACCP tools. Shared Traceability is a new generation traceability software that uses modern technologies (blockchain, mobile, QR codes, cloud) to make traceability process easy and intuitive. It makes recording safe, and allow you to sharing traceability information not only inside your company, but across corporate boundaries.

What do you get by using Shared Traceability:

-

-

-

- An easy way to collect traceability information anywhere: on the shop floor or in the field

- A secure storage in the cloud and data retrieval from anywhere

- Ability to access the right information when needed; be prepared for a recall, limit recall scope required minimum and uncover the reason(s) for the problem(s)

- Securely share traceability information with supply chain partners if you chose so. Each partner can see and analyze traceability information as product moves through the production stages: from the raw ingredients to finished product.

-

-

What can you do with Shared Traceability:

-

-

-

- Record everything that happens with the product batch, serialized inventory or an asset as a blockchain transaction

- Record producing or receiving components and raw material batches

- Record product movement through the production process

- Record building of assemblies, generic and serialized

- Record products conversions and splitting during the manufacturing process

- Record observations during the process stages (various measurements, what was done, etc.)

- Enter any required information into the system

- Do all tracking anywhere using mobile devices for barcode / QR code scanning and data entry

- All information submitted from the mobile devices is immediately available to all authorized users

- Review details and the entire history of each product batch by scanning QR code, or via the web dashboard

- Review composition of each product batch, drill down through sub-assemblies to individual products, review all history and data for each with one click

- Quickly find where a specific product lot had been used, where it was distributed

- Invite downstream and upstream partners to join the network and share traceability data across the entire supply chain

- Optionally let end users scan QR code and review a "product story"

- Use together with QR Inventory for more comprehensive internal inventory management and traceability, or as a stand-alone traceability solution.

-

-

“Importantly, you get all of this functionality at a fraction of the price other inventory management and lot tracking systems would cost you,” says Dr. Alex Heiphetz, CEO of AHG, Inc., the company that authored Shared Traceability. “Even more important is the fact that you can start using Shared Traceability immediately. It does not require any setup and a learning curve is non-existent.”

About Shared Traceability and AHG, Inc.

Since 1994 AHG, Inc. develops integrated cloud - mobile applications that are modern, innovative, can be implemented quickly and increase your company productivity and efficiency. The company specializes in the areas of assets and inventory management, data collection, project management and workflow automation. AHG uses modern technologies (mobile, cloud, smartphones, QR codes, NFC) to make routine business tasks faster and easier to complete, eliminate data loss and errors, and streamline information exchange within your organization.

For more information on Shared Traceability and other inventory and process management solutions, please see web page at http://www.qrinventory.net/shared-traceability/, or contact Dr. Alex Heiphetz,