Industries Where Barcode Laser Marking Is Growing

Laser marking refers to the use of lasers to etch permanent identification marks such as graphics and characters on products and parts, making it easy for manufacturing firms in the medical, automotive, military, aerospace, metallurgy and electronic industries to identify their parts and ensure traceability.

Laser marking refers to the use of lasers to etch permanent identification marks such as graphics and characters on products and parts, making it easy for manufacturing firms in the medical, automotive, military, aerospace, metallurgy and electronic industries to identify their parts and ensure traceability.

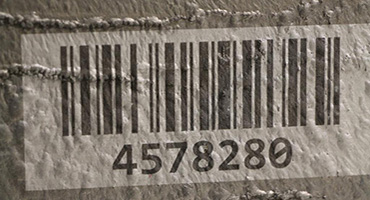

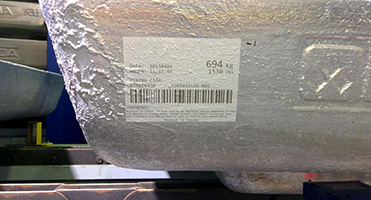

Since safety and security is of paramount importance in these industries, laser marking helps ensure clients that the parts they are getting are authentic and of high-quality. Laser marking is usually used to mark parts used in larger applications with logos, barcodes and model numbers.

The laser marking process is unlike conventional marking processes that involve the use of physical tools, chemical products, dot peen, etc. Such processes work by removing part of the substrate, transmitting ink onto the surface or engraving/printing using solvents and other material additives.

Laser marking utilizes a non-contact approach ensuring that the marked surfaces are free of damage and contamination.

Benefits of Laser Marking

The following are some of the benefits of laser marking

Zero contamination

With laser marking, identification marks are etched onto parts without the need for chemicals, printing ink or material additives. This ensures zero-contamination - particularly beneficial for manufacturers of medical tools and equipment.

Speed

Laser marking is incredibly fast when compared to traditional marking techniques. For faster processing, laser marking tools can be added to the production/assembly line of manufacturing plants.

Flexibility

Laser marking can be used on a variety of materials including metals, plastics, rubber, natural materials, silicones, and polyamides.

Improved visibility and durability

Identification marks made using laser marking process have very high visibility when compared with those made with traditional printing/engraving techniques. Since the marks are etched directly onto the material’s surface, they last as long as the material itself. Laser marking is permanent, highly durable and very resistant to abrasion.

High precision

Laser marking is highly precise, enabling the marking of 1-point fonts, graphics with small geometries, and delicate markings. It ensures consistent high-quality results and clear legibility on even the most delicate graphics.

Let’s take a look at the top 5 industries where laser marking is in high growth.

Medical Industry

The Food and Drug Administration (FDA) mandates that all medical products and tools have unique identification marks (UID). As such, all medical tools and implants have to be marked including but not limited to the following:

- hip stems

- bone plates

- catheters

- bone screws

- surgical tools and devices

- minimally invasive instruments, etc.

In addition, medical tool manufacturers must ensure that these marks are indelible, traceable and completely readable throughout the equipment’s life cycle.

Laser marking provides the medical industry with an easy and effective means of meeting the FDA’s requirements. The process of laser marking enables the annealing of high resolution bio-compatible markings on medical equipment aiding the traceability of implants and instruments.

It also ensures that no damage is done to the chemical passivation of medical tools which is required for corrosion resistance and to prevent germs from embedding themselves within the material. This helps medical tools to maintain their anti-corrosive coatings even after years of sterilizations, cleanings, and usage.

Automotive Industry

Due to its ease of operation, low cost, efficiency, durability and indelible nature, laser marking is the ideal marking process for the automotive industry.

In an effort to improve safety and quality, traceability has become an important requirement for automotives manufacturers and their suppliers. As such, more and more automotive assembly plants and parts manufacturers are beginning to use laser marking to identify their products.

Whether it is a pattern, logo, plain code, serial number, warning sign, label nameplates, Data Matrix Codes (DMC), transparent button marks, or certification markings on glass, virtually all automotive parts require some form of marking etched onto them.

Unlike traditional marking processes, laser marking employs a non-contact, highly efficient and precise method of marking parts without the need for additional material. Within the automotive industry, laser marking can be used in the following applications:

- engine tag

- car launching and controlling tag

- car body and VIN code tag

- door and tire pressure tag

- cooling system and air-conditioner tag

- barcode and key tag

- oil tank tag

- Warning tag within airbag restraint system

- wheels, etc.

Laser marking is also suitable for marking all automotive components including car glass and hub.

Aerospace Industry

The aerospace industry isn’t restricted to just commercial and private airlines, it also extends beyond that into the research, engineering, design, and maintenance of spacecrafts. Needless to say, the aerospace industry is held to incredibly high safety and quality manufacturing standards.

Laser marking ensures that these standards are met by etching accurate, very precise and easily identifiable marks without affecting or damaging the parts being worked on. This means that the safety and quality of the final product isn’t compromised.

Laser marking can be used on all kinds of materials including glass, plastic and other common types of metals used in the aerospace industry such as stainless steel, aluminum, and titanium. It can be used to engrave aeronautical parts with identifying marks, barcodes, labels, logos, graphics, serial numbers and date code.

Laser marking is used in the following aerospace applications:

- Markings for cylindrical parts

- Circular markings on screw heads

- Markings on arm extremities and crankcases

- Day and night markings on cockpit avionics panels

Electronics Industry

Since laser marking systems make it easy and cost-efficient to maintain consistent product quality and improve process flow by automating the marking of parts, they are particularly beneficial to the electronics industry.

Laser marking can be used to etch electronic components and printed circuit boards with machine-readable and solder-resistant laser markings. This guarantees trademark protection, quality assurance, traceability and accurate identification, thus ensuring a flawless quality assurance process throughout the life cycle of the electronic products.

Laser marking is used in the following applications:

- Etching of 2D barcodes such as Data Matrix Codes

- Engraving of alphanumeric characters

- Using linear barcodes to identify parts and components

- Marking products with logos and other customized data

- Marking of electronic components manufactured using ceramic, metals, metalloids (silicones) and synthetic materials such as epoxy resin.

Military/Defense Industry

The U.S. Department of Defense (DOD) requires the use of Item Unique Identifier (IUID) standards MIL-STD-130M for all discrete entities including but not limited to relevant business, enterprise information environment, intelligence, and mission area transactions.

This requirement also applies to manufacturers in other industries.

Since laser marking can withstand the harsh conditions that military products and parts are subjected to, it is ideal for use in IUID applications for the defense industry.

Laser marking can also be used to engrave identification marks and graphics on various tools and equipment ranging from knives and firearms to military vehicles and helicopters. This ensures traceability of all military equipment, leading to better management and organization of military assets.

Conclusion

Thanks to the numerous advantages of laser marking: speed, flexibility, permanence, contamination-free and highly automated nature of the laser marking process, it is the ideal engraving technique for manufacturing firms in the above industries. It also helps manufacturers to keep to the standards required by the Department of Defense, FDA and other federal and state government agencies.

Laser marking is essential for traceability, inventory control and renewal, product quality validation, production flow control, as well as long-term product liability and reliability. In coming years, it will become indispensable to uniquely identify parts, during manufacturing processes.

Author: Normand Lemieux, BBA

Normand is a well-rounded and autonomous marketing professional with a recent specialization in web marketing. He thrives to share experiences, to apply knowledge, to learn new things and get stuff done. Find out more about laser marking at www.Laserax.com.

Other articles that may interest you:

Follow The Bar Code News(tm) on Facebook and Twitter.