RFID Leader Marks & Spencer Drives Apparel Sales with Accurate Inventory Tracking

The Challenge

The Challenge

As one of the leading retailers in the UK, Marks & Spencer (M&S) is focused on providing an exceptional customer experience to the 21 million shoppers who visit its stores each week. With the constant changes and improvements to the retail landscape, it’s more important than ever to provide shoppers with consistent and accurate product availability in-store and online. Traditionally, M&S relied on optical scanners to track inventory – using barcodes to scan each item within centimeters of the scanner and scanning a maximum of 400-600 items per hour. However, barcode scans are only as accurate as the person operating the scanner to process checkout and returns, thus they are prone to ongoing human errors. In addition, barcodes don't provide any insight into manual restocking operations, and they were never designed to support rapid cycle counts. The combined human errors and losses drove inventory accuracy below desired levels, reducing the optimal shopping experience and limiting full profit potential. In order to better manage stock levels and ensure that the correct product mix is on display, M&S was looking for a way to make inventory tracking more efficient and accurate.

The Solution

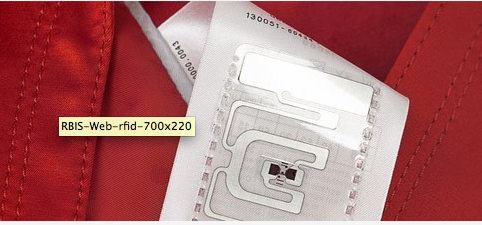

In 2003, M&S turned to Avery Dennison as a pilot partner for item level RFID on clothing in its High Wycombe store near London, tagging 10,000 men’s suits, shirts, and ties. Because of increased inventory accuracy during the trial, M&S quickly expanded the RFID process across apparel in 2005, and by 2007 the technology was being used in 120 stores. Now, in 2012, M&S has rolled out Generation 2 RFID technology across the company’s 200 top grossing stores and expanded RFID tagging to all clothing and home wares. Working closely with M&S, Avery Dennison has developed RFID tags specific to the retailer that are fully integrated into a complete range of labels and tickets. M&S now uses over 100 million RFID tags per year on clothing. The tags can be read when a scanner is up to a meter away, making the inventory scanning process faster and more efficient. “Having accurate stock information is a driver for our whole business, especially when it comes to multi-channel,” said Kim Phillips, head of packaging at Marks & Spencer. The RFID scanned information is then transmitted to M&S’ central stock database, logging an automatic update of the store stock position is. Subsequent comparison with the stock profile for the store triggers a replenishment order for any missing stock, again making the restocking of merchandise more efficient.

The Benefit

RFID technology from Avery Dennison has helped improve the M&S customer experience, by ensuring that the right products in the right sizes are available when and where shoppers are searching for them (whether it’s online or in-store). According to Phillips, “The RFID partnership with Avery Dennison is allowing us to replenish stock from the distribution center more accurately, making more garment sizes available to more customers. RFID technology from Avery Dennison continues to prove its value over and over again.” The technology is also enabling inventory tracking to be carried out up to ten times faster than with traditional optical scanners, making the process not only faster and more accurate but significantly more efficient. “Avery Dennison has supplied us with almost one billion RFID tags with no data loss or duplication. The business case for expanding RFID across our entire supply chain is very strong,” said Steve Finlan, retail director at Marks & Spencer.

About Marks & Spencer

Marks & Spencer is of the UK’s leading retailers, with over 21 million people visiting its stores each week. Offering stylish, high quality, great value clothing and home products, and outstanding quality foods responsibly sourced from around 2,000 suppliers globally, M&S has over 700 stores in the UK.

About Avery Dennison

Avery Dennison is a global leader in labeling and packaging materials and solutions. The company’s applications and technologies are an integral part of products used in every major market and industry. With operations in more than 50 countries and 26,000 employees worldwide, Avery Dennison serves customers with insights and innovations that help make brands more inspiring and the world more intelligent.

Have the latest Bar Code News delivered right to your inbox. Sign up for our Newsletter!

If you enjoyed this article, check out some similar ones. And please let vendors know that you've seen them on barcode.com!

Leading Bar Code and RFID Software Developer Provides One-Click Labeling Solution

Barcode Label Solution For A Medical Rental Company

TIMEpoint Biometric Data Collection

Barcode Labeling Software – WaspLabeler +2D

Direct Thermal vs. Thermal Transfer Label Printers

Case Study: Custom Product Labels with Epson's SecurColor Printer For GEMFormulas Natural Remedies