Bar Codes and Packaging

Bar codes and Packaging

This article discusses issues to consider when placing or designing a bar code on a package. A number of links to industry standards documents are available at the end of the article. Before printing thousands of labels it is recommended you consult with a bar code professional to make sure to get it right the first time.

1.Number assignment best practices - getting the number right

Usually the brand owner is responsible for assigning the bar code number. Whoever does it, extreme care should be taken to ensure an old number isn’t accidentally reassigned to a different product, or a new number isn’t accidentally assigned to more than one product. Often this happens when multiple copies of the product data base are kept. Good communication between various functions that must share the data base is not a sufficient solution to the possibility of number assignment mistakes. Build out the possibility with an airtight procedure that draws on one central number assignment agent and one data base.

And don’t forget that different sizes, weights, colors, flavors and other variations must be uniquely numbered. If your bar code numbers don’t reflect product distinctions, the sales and inventory replenishment figures can’t differentiate them either.

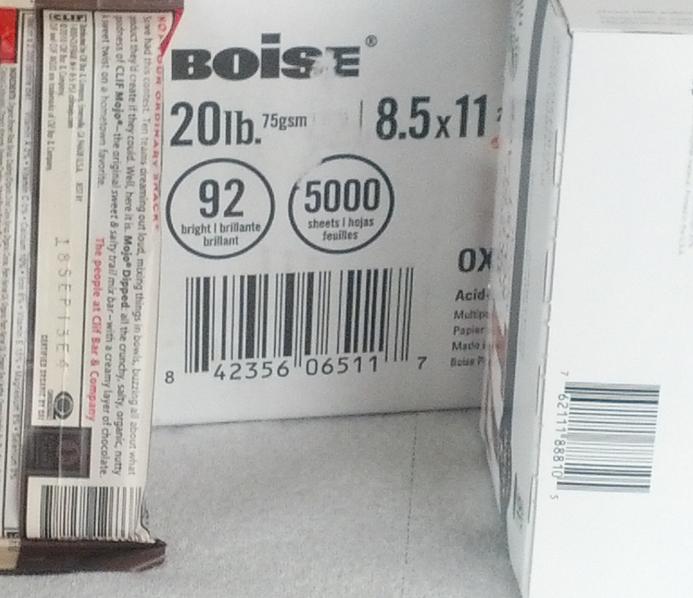

It is also very important that the correct symbology is used. Retail point-of-sale (POS) requires a UPC or one of its variants (EAN and JAN in other areas of the globe). (1) (2-2)

2.Bar code design file

If at all possible create the bar code using a graphics program, not a font program. The problem with font programs is that they don’t always integrate into the larger graphics design file and can get corrupted. The bar code may still look like a bar code but it doesn’t decode properly.

Whatever kind of design program you’re using, design and use the bar code file at its final size (magnification). Never-never-never scale the bar code to make it fit the space left for it in the graphics design.

If your customer provides the bar code design file, make sure it is designed correctly or your process. It should have the correct bar width reduction factor and size (magnification) and, of course, the correct number assignment for the product package.

Always include the entire human-readable interpretation with the bar code and generate the bar code and human-readables together, never as separate operations.

UPC/EAN bar codes on consumer point-of-sale packaging should never be smaller than 80% magnification for offset printing, and never smaller than 100% for flexo printing. Unnecessary truncation (cutting down the height of the symbol) is not permitted by the GS1 specification. When it is absolutely necessary due to space limitations, it should be minimized. Truncation makes scanning the bar code less omni-directional, slowing down the POS process and aggravating retailers.

More on Barcode Printing Specs (7).

3.Symbol placement

The GS1 specification requires the bar code to be located on or near the natural bottom of the package. The presence of a bar code in a location on the package which slows the point-of-sale process can trigger retailer charge-backs.

A package should never display more than one bar code on any side or facet.

Detailed specifications are available on the GS1.org website.(1) (3)

4.Verify at every production step

The best time to verify is during a production process. Post-process verification is too late to make any essential adjustments to improve the quality of the bar code. Verification of pre-press bar code images may show negative bar width error because press gain has not yet occurred. Minus-side bar width errors should be approximately equal to design-imposed bar width reduction.

Pre-production is a great place to check symbology, encoded data against human-readables, check digits, symbol location and quiet zones.

Use an ISO-compliant verifier, not a scanner. Testing with a partially ISO compliant or non-compliant verifier is meaningless. Testing with a scanner is only go/no-go testing for that one scanner. It doesn’t signal emerging problems and doesn’t replicate the way other scanners behave.

5.Use your Verifier—and your head

Verifiers test and grade the ISO attributes of the bar code, but not whether the human-readables and the encoded data match. Nor do verifiers test for symbol truncation or location, or whether the correct symbology is present. Some verifiers do not test the symbol for correct structure, such as Application Identifiers in, for example, a coupon code.

Choosing a bar code font, placement, bar code printing source and dealing with other variables requires patience and attention to detail. Consulting with an expert can save you time and money in the long run and we encourage you to consider bringing in an expert.

Written by John Nachtrieb

Mr. Nachtrieb has 30+ years of hands-on experience in barcode technology. His team imaged the film master for the first commercially scanned barcode in North America (1974). His specialty is barcode quality. He created and hosts a highly customized barcode quality seminar which has been presented to 100's of companies, reaching thousands of quality-concerned people, helping them to avoid barcode problems and manage barcode-related risk.

(Assistance by Craig Aberle)

About Barcode-Test

A 30-year veteran of the bar code industry, John Nachtrieb and his company Barcode-Test help provide solutions for customers' bar code quality challenges. He assists product managers, package printers, and suppliers by managing bar code related risk, and supporting bar code integrity over the long haul. You can find more of his writing on bar code quality at the Barcode-Test blog.

Official Sources of specifications and informational guides

(1) GS1 General Specifications - http://www.gs1.org/docs/gsmp/barcodes/GS1_General_Specifications.pdf

(2) GS1 Bar code Implementation - http://www.gs1.org/barcodes/implementation

(3) GS1 Pick the Bar Code Placement - http://www.gs1.org/barcodes/implementation#9

(4) Getting Started With AIDC - Free white paper By AIMGLOBAL - http://www.aimglobal.org/?page=get_started

(5) Barcode Quality Step By Step - Connecting the Dots from the Verification Report to Solving Your Barcode Problems - Free white paper by Barcode-Test

(6) Assorted Bar Code Resources - https://barcode.com/assorted-bar-code-resources.html

(7) Bar Code Printing Methods -http://www.gs1.org/barcodes/technical/bar_code_printing_methods

(8) Why Bar Code Quality is More Important Than Ever - How Self-check out, Automated Sortation and Drug Dosing Require Higher Quality Codes -http://www.barcode-test.com/barcode-tutorial/bar-code-quality-more-important-than-ever/

Treat yourself! Subscribe to the Bar Code News - daily, weekly or monthly. Free for members of the industry and bar code enthusiasts. Your privacy is respected - we never sell or rent our email lists.

Was this article useful? May we suggest bookmarking it in your browser? Have suggestions for us? Please let us know. We live to serve the bar code community.