How To Create A More Efficient Warehouse Using Barcodes And Labels

As government and industry regulations proliferate and the penalties for noncompliance get harsher, companies are finding that they must strive for accuracy as well as efficiency in every aspect of their business. In fact, 17 percent of the respondents in an Aberdeen Research poll declared that meeting current and future regulatory requirements was among their greatest issues.

As government and industry regulations proliferate and the penalties for noncompliance get harsher, companies are finding that they must strive for accuracy as well as efficiency in every aspect of their business. In fact, 17 percent of the respondents in an Aberdeen Research poll declared that meeting current and future regulatory requirements was among their greatest issues.

Aberdeen Research also shows that 42 percent of respondents considered their operating costs to be too high, and 24 percent cited reduced budgets. One area with an outsized impact on operational effectiveness and customer satisfaction is the warehouse, yet many companies treat the warehouse as an afterthought. These companies keep using the same tools and methods, year after year, and they pay the price in lost warehouse efficiency. They resist improving warehouse efficiency because they think it’s too expensive or not cost effective.

In reality, improving warehouse efficiency can be accomplished with a simple change such as instituting a label program that clearly identifies each item for picking and putaway. Here are a few ways labels will improve warehouse operations.

Improved Organization

Using a consistent style and size label for every item helps ensure that items are put away and picked correctly. The uniformity of the printed label can give a warehouse a more organized appearance, even if you don’t make any other changes. Keeping items neat and organized is a key principle of lean thinking, and adopting lean techniques is one of the best ways to improve efficiency — whether on the shop floor or in the warehouse. Improving warehouse organization will help reduce the incidence of lost items, which will in turn help increase your “perfect order” rate. In turn, this results in happier customers and fewer production interruptions because of lost or delayed materials.

Better Efficiency

Labels do more than just improve the consistency and readability of inventory. They can actually help simplify processes. For example, using different colored labels for materials that require special handling or storage techniques can improve safety and reduce spoilage without any additional labor.

Labels do more than just improve the consistency and readability of inventory. They can actually help simplify processes. For example, using different colored labels for materials that require special handling or storage techniques can improve safety and reduce spoilage without any additional labor.

Material handlers can easily sort goods to be put away by label color, so they can move multiple items at one time, reducing the number of trips to distant warehouse locations. Knowing that items with blue labels go in cold storage, or that red labels go on caustic chemicals that require safety precautions can make it easier for warehouse personnel to follow instructions. Different sizes or shapes for labels can serve the same purpose as colors — the secret to improved warehouse efficiency is using the labels consistently.

Fewer Errors

Some warehouses try to save money on bins or crates by storing items in the box where the supplier shipped the parts. The supplier’s label may not include your internal item numbers, so people write the item number on the cartons when they are put away. An even worse practice is to re-use unlabeled cartons, because then there may be multiple item numbers on the carton. That is a recipe for picking errors that irritate customers or cause production delays.

Printed labels are simply easier to read than handwritten scrawls, and a consistent approach to the format and positioning of the labels helps material handlers know where to look to identify items. This makes the overall operation much more streamlined; decreasing the likelihood that material handlers will pick the wrong item or put material away in the wrong location.

Add Data Collection Barcode Readers

Add Data Collection Barcode Readers

Adding a simple barcode to the printed label can reduce errors even further because users don’t have to manually enter item numbers into the computer system when picking, and it reduces the likelihood that they will simply misread the number.

There was a time a few years ago when adding barcode readers could be an expensive proposition. Today, effective readers and scanners can be acquired for under $100. Barcode-reading software can be installed on mobile devices such as cellphones or tablets — often for free. The combination of low-cost data collection equipment and clearly printed labels will help you create a more efficient warehouse without a heavy investment, extensive retraining or disruption to existing processes. The result will be lower costs, fewer errors and happier customers.

---

About the Author:

About the Author:

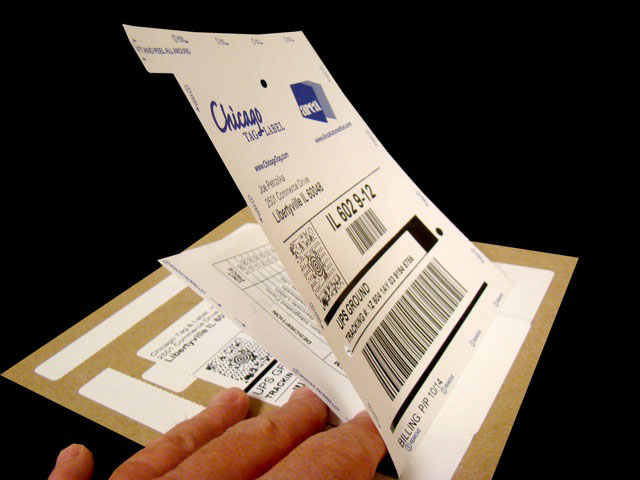

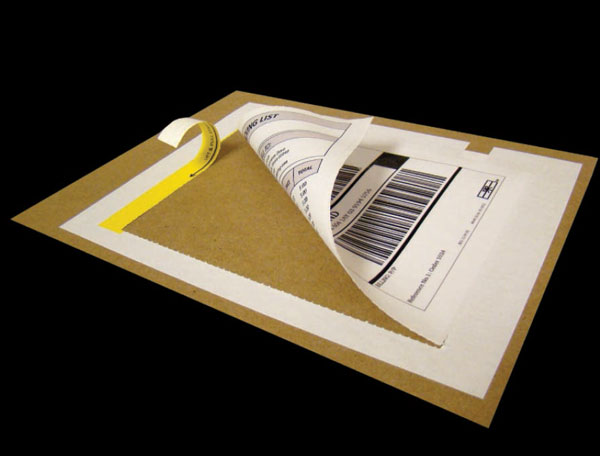

Don Amato is Vice-President, Sales of Chicago Tag & Label. Chicago Tag & Label manufactures form labels, labels and tags that deliver solutions to industries such as retail, manufacturing and distribution.

---

Other Barcode news of interest: