Case Study: Industrial Food Label Barcode Printing

The Gourmet Nut Company has replaced manually applied labels to their flexible packs of nut products with two Linx TT5 Thermal Transfer Overprinters, and as a result has improved their efficiencies and packaging quality.

The Gourmet Nut Company is a specialist coater of several gourmet nut products. They coat nuts from 3mm granulated hazelnuts up to whole, large nuts (such as macadamias and pecans).

Close to 1,000 tonnes per annum of roasted and coated nuts are sold to virtually all major retailers and wholesalers throughout Australia. Products are also exported across Asia Pacific and New Zealand.

SITUATION

The Gourmet Nut Co.’s dramatic sales growth had vastly outpaced its labelling process. The company was applying three separate labels by hand: one on the front, two on the back. They wanted an automated solution to increase efficiency, improve packaging quality, and increase packaging consistency.

They also needed to save time and money by removing manual labour, such as changing a whole film wheel whenever they wanted to change products on the line.

The specialty nut roaster also wanted to reduce packaging costs. As a small business, too much working capital was tied up thousands of reels of film for individual products across its 12 product lines.

The coding solution needed to print alphanumeric information and barcodes on both sides of a flexible film packet at once. It also needed to be able to print Chinese characters for export products. Product ID, barcode and nutritional codes needed to be clear, scan reliably in customer warehouses, and look professional.

The solution had to be able to code on generic film (to reduce packaging inventory and costs), and also have the capability for new products to be created easily (to trial new flavours, for instance).

SOLUTION

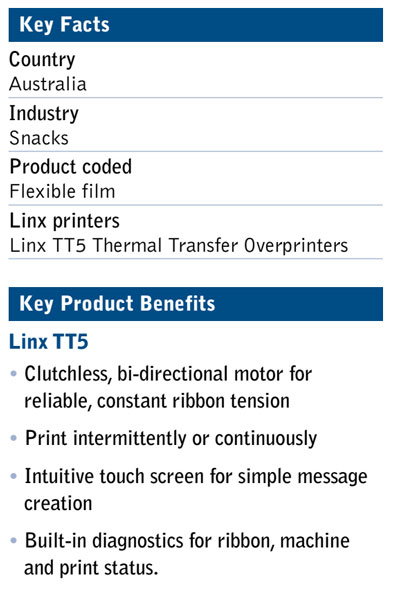

The Gourmet Nut Co. chose two Linx TT5 Thermal Transfer Overprinters, supplied by Linx distributor Matthews.

The TTO printers are configured as master/slave, where the one user interface has control over both printing devices (a strong advantage of this coder). This reduces tasks and makes set-up easier, with only one printer needing to be setup to cover two printers.

The coders simultaneously print the product ID on the front, along with ingredient panels and best-before and batch codes on the back.

|

“I felt quite comfortable with Matthews, and it’s good to know that we have not only ended up with quality machines that are absolutely right for our business, we also have knowledgeable people there to help us whenever we need them. We have ended up with quality machines that are absolutely right for our business.” — Ray Rust, Managing Director, The Gourmet Nut Company

|

OUTCOME

The Gourmet Nut Co. is very pleased with the coding solution. It has saved a huge amount of time by removing manual labour, improving efficiency in the process and lifting packaging quality and consistency. Generic film has freed working capital (and physical storage space) from being tied up in film inventory.

The operators find the TT5s very easy to use: simply changing a code in the system has replaced the manual task of changing an entire film wheel whenever they want to change products. The colour touch-screen, with its simple-to-follow instructions, has minimised errors. A bonus has been fewer ribbon changes due to the long standard ribbon (1,000m).

Both generic film and the simple programmability for codes has meant The Gourmet Nut Co. can easily add or trial new products (rather than wait for film for new products to be traditionally printed).

---

www.linxglobal.com/tto www.matthews.com.au

Linx is a registered trademark of Linx Printing Technologies Ltd. Linx Printing Technologies are an internationally-renowned supplier of a range of coding and marking solutions including Continuous Ink Jet, Laser Marking, Case Coding and Thermal Transfer printers. Linx Global provides coding and marking solutions to a wide range of industries which include the food, beverage, pharmaceutical, cosmetics, automotive and electronic industries, where product identification codes, batch numbers, use by dates and barcodes are needed.

---

Other Barcode case studies of interest: