A Mobile Approach to Inventory Management & Equipment Accountability

Valley Proteins streamlines physical inventory processes across plants for increased accuracy and efficiency

Valley Proteins streamlines physical inventory processes across plants for increased accuracy and efficiency

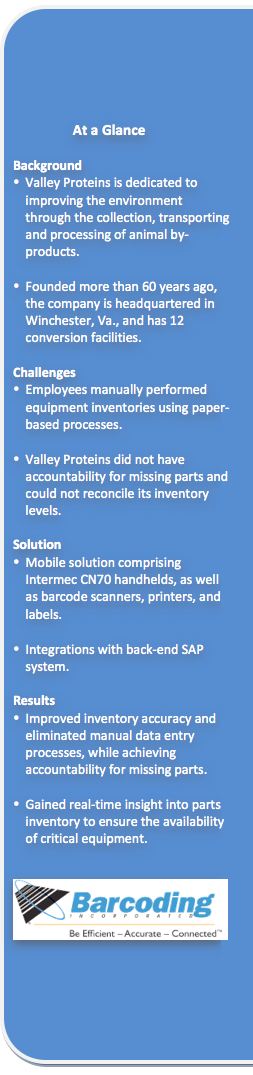

Background

Valley Proteins, Inc., is dedicated to improving the environment through the collection, transporting and processing of animal by- products. For more than 60 years, Valley Proteins has set the standard in creating renewable resources for the development of quality animal and pet feed ingredients. Headquartered in Winchester, Va., Valley Proteins has 12 conversion facilities throughout a 17-state area in the Mid-Atlantic, eastern and southwestern regions of the United States.

Challenges

Within Valley Proteins’ warehouses, employees manually performed equipment inventories. The company relied on paper-based processes to capture data in order to enter it into its backend SAP system. This data entry method was both time consuming and increased the likelihood of human errors, and therefore, inaccurate inventory accounts. In addition, Valley Proteins did not have any accountability for its parts. If a part went missing, the company was unable to reconcile its inventory accounts and write off parts that are lost in terms of work orders.

Solution

Valley Proteins sought a solution to streamline the physical inventory processes for tracking its equipment and parts. Barcoding, Inc., a Baltimore-based systems integrator and enterprise mobility expert, recommended CN70 handheld computers from its long-time partner, Intermec, and provided Valley Proteins with hands-on demos and competitive pricing.

“One of the important things that we were looking for was the ruggedness of the devices,” said Nelson Castro, director of program management, Valley Proteins. “The devices needed to withstand drops on concrete floors.”

Barcoding also provided Valley Proteins with barcode printers, scanners and labels to round out the solution, which Valley Proteins then integrated with its back-end system. With this mobile solution, Valley Proteins is able to load inventory from the back-end SAP system (with detailed information down to the exact shelf, row, bin location, etc., of the equipment) onto the device by scanning a barcode. Then, the company forms an inventory count on each of these parts and loads them into the device into a “document list.” Finally, Valley Proteins transfers these counts to its back-end system to verify and reconcile its inventory.

Results

Valley Proteins has significantly improved its efficiency in performing physical inventory and increased its inventory accuracy. Because the company is able to reconcile its inventory, it has full accountability of all of its parts – it knows exactly how many parts it is using, how many are misplaced, and how these numbers specifically affect its overhead costs. This insight is especially beneficial for Valley Proteins’ accounting department.

At the plant level, employees have accurate, real-time inventory levels on hand and can easily ensure that they are keeping critical parts on the shelf. Also, for maximum uptime, Barcoding’s team is available 24/7 for device maintenance and replacement, if needed.

“Going from not having any inventory methodology in place to being able to expense and issue parts is a huge advantage for our company,” Castro added. “The Intermec devices are ideal pieces of equipment and are easy to use and reliable. Barcoding did a great job recommending and procuring all the right hardware to help our solution come together.”

In the future, Valley Proteins plans enlist Barcoding’s help to implement a proof-of-delivery (POD) system. When an employee arrives at a customer’s location, the POD system would record grid coordinates and confirm that the company has serviced a particular account.

About Barcoding, Inc.

Barcoding, Inc. is a national systems integrator, specializing in the development, deployment, and management of supply chain and mobility systems based on automated data capture and wireless technology. More than 2,500 organizations depend on Barcoding, Inc. as their trusted advisor for barcoding and radio frequency identification (RFID) applications automating operations in: field service, food and beverage, healthcare, manufacturing and distribution, retail, transportation and logistics, and wholesale inventory. For more information, visit www.barcoding.com.

More case studies about barcodes used in manufacturing;

Please be sure to click on the Solutions tab above, to see hundreds of other case studies. Thank you for visiting www.barcode.com