The Most Common Cause of Barcode Failure

(Our thanks to John Nachtrieb of Bar-Code Test for this article.)

(Our thanks to John Nachtrieb of Bar-Code Test for this article.)

Having spent many years studying, interpreting and explaining the ANSI/ISO 15416-1 specification governing the quality of printed barcodes, I'd like to believe that the most common cause of barcode failure is some obscure, difficult to detect and even more difficult to remedy parameter. But it's not. It's simpler than that.

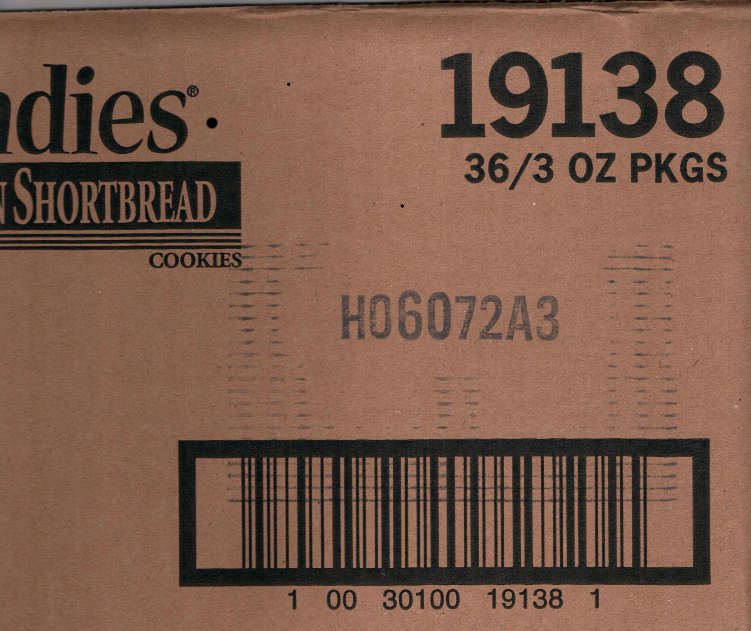

One of the most common causes of barcode failure?

One of the most common causes of barcode failure—and we’re talking linear barcodes here—is the most obvious, most easily detected and most preventable cause—and isn’t one of the ANSI/ISO 15416-1 parameters. It is quiet zone violation.

Quiet Zone violation is the most easily detected and preventable cause of barcode failure

There is no scientific data to substantiate the claim that quiet zone failure is the most common cause of barcode failure—the evidence is purely anecdotal. But I have heard it repeatedly from numerous participants in the barcode industry – and I don’t have any trouble believing it, because I see it all the time.

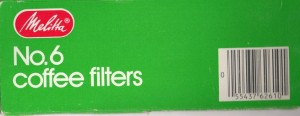

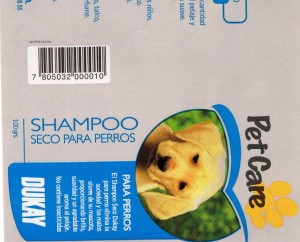

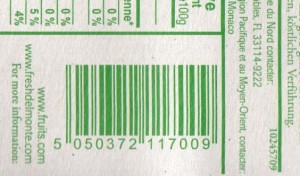

(Images courtesy of John Nachtrieb.)

Often the encroachment is subtle, such as in the GS1-14 samples above and below. The verification report shows that the magnitude of the violation is one module: the quiet zones should be > 10 modules and the right quiet zone is 9 modules wide.

The error was not a design mistake. The error occurred when the printer applied excessive pressure to the imaging plate and literally squeezed one module of width right out of the quiet zone by spreading the symbol and the surrounding bearer bars.

Barcode failure due to quiet zone violation is usually caused by ignorance, not some technical issue

The lesson here is that the specification provides for a minimum quiet zone width—but there is no maximum. Bigger is always better. When there’s available space, why be sparing?

Most quiet zone errors are not this subtle, as the examples below illustrate. These are simple design mistakes born of ignorance.

But most mistakes are also completely preventable and without an obvious cause. In almost every case I’ve seen where at least one quiet zone has been violated, there is sufficient available real estate on the package or label. There was no causal factor that drove the design into a quiet zone encroachment.

Advancements in scanning technology have made scanners increasingly tolerant of quiet zone violations. Why hasn’t the ANSI/ISO specification likewise been relaxed? The specification remains, for a variety of reasons.

The scanning environment contains a huge population of very old bar code scanners that are not tolerant of too small quiet zones, and since most quiet zone problems (another non-scientific observation) are not due to limited space for the barcode, why should the specification be changed?

Some violators have pleaded “not guilty” because quiet zones are not an ANSI/ISO 15416-1 attribute—they are a factor in Traditional Verification. Didn’t the ANSI/ISO specification supersede the older Traditional specification?

Traditional verification was never really a specification because it never incorporated a testing protocol that everyone agreed upon. And besides all of that, if there is an attribute of bar code quality that impacts on barcode performance, isn’t that sufficient cause to pay it proper attention?

About Barcode-Test

A 30-year veteran of the bar code industry, John Nachtrieb and his company Barcode-Test help provide solutions for customers' bar code quality challenges. He assists product managers, package printers, and suppliers by managing bar code related risk, and supporting bar code integrity over the long haul. You can find more of his writing on bar code quality at the Barcode-Test blog.

See related articles:

Follow Us on Facebook - https://www.facebook.com/thebarcodenews