Adopting Next Gen Labeling Technology Enhances Enterprise Agility and Reduces Costs

(Editor’s note : This is an abstract of a white paper – the link to the full paper is available below. )

The new generation of label management solutions gives many enterprises an opportunity to reduce costs, improve agility, and reduce the risk of production shutdowns and non-compliance with labeling requirements. These benefits are delivered because modern label management solutions enable organizations to consolidate and automate redundant label development and maintenance tasks that today are typically carried out by a variety of developers and operations staff at each facility that produces labels.

Labeling is frequently considered a background process that doesn’t get any attention until it causes a problem. As a result, bar code and RFID labeling practices and software have become dated at many enterprises, failing to keep pace with changing business needs.

The Current State of Enterprise Labeling

Enterprises don’t have different accounting standards for each office or department. Similarly enterprises do not give their salespeople the freedom to choose which CRM system they will use to support their individual accounts. Yet they often allow inconsistency in their labeling operations and are not aware of the costs and problems that inconsistency creates.

Decentralization also adds time and cost to labeling operations. Consider what would happen at a company with decentralized labeling whose customer requested a change to the labels on its shipments.

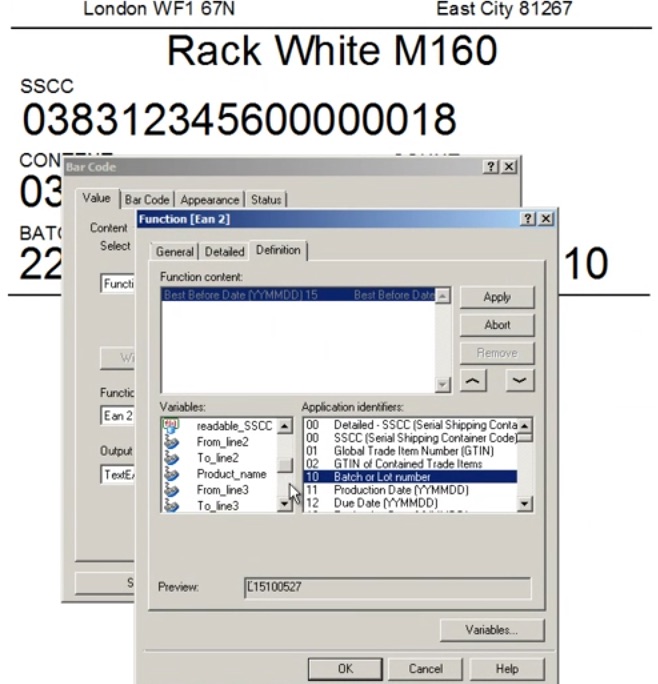

It is common for each distribution center, factory or other facility within an enterprise to produce its own labels for shipments, inventory control, and other processes. Each facility typically has several different label printers and maintains a library of label templates for the internal processes and customers it supports. Each facility also may have its own label design and management software. That leads to thousands of possible configurations, even for labels for shipments sent to the same customer. Consistency suffers because different software packages and printers treat bar codes, fonts, graphics, and other label elements differently. The enterprise may not be aware of these inconsistencies because each facility only sees the labels it produces. Customers, however, would likely notice the inconsistency from their supplier.

Benefits to Modernizing by Centralizing Labeling

The modern generation of centralized labeling solutions can give users the timely access and flexibility they need at the local level while ensuring consistency across the enterprise. Modern systems maintain a single version of each label file and make the file easily accessible to the people and systems that need it, regardless of their location. This approach eliminates inconsistency (and thus reduces errors and the risk of non-compliance) while improving control for label system administrators and convenience for users.

Migrating from decentralized labeling to a modern, centralized solution generally helps organizations in four ways:

-

Improves agility by reducing the time needed to create, maintain and update label files, introduce new products, and respond to customer requests. Enterprises that convert from decentralized labeling often find thousands of redundant label files that can be eliminated and consolidated into a few consistent templates;

-

Raises quality by preventing inconsistency and eliminating latency from exchanges with enterprise systems; enhanced quality also helps prevent shipping delays and production line shutdowns that result from labeling errors or system failures. Tighter control prevents mislabeling, which reduces the risk of recalls;

-

Reduces direct and indirect costs by lessening the labor, time, and expertise required to maintain label formats, make changes, and create new labels. Indirect savings come from reduced labeling errors, improved compliance, and better brand consistency;

-

Enhances collaboration with business partners by making the enterprise more responsive to change requests and by enabling advanced labeling techniques that can help deter diversion and counterfeiting.

Labeling operations are often overlooked in the drive to improve business operations. Centralizing labeling operations gives enterprises the opportunity to improve label quality, accelerate speed of execution, and improve responsiveness to customers and supply chain partners. To attain these benefits, organizations need to change their processes and migrate to a modern labeling management system.

Despite the need to change, enterprises typically save money by making the migration because centralized labeling provides a lower long-term cost structure. It eliminates the need for redundant effort, reducing the cost basis for creating and maintaining label files. Additionally by reducing the time needed to develop new labels it also lowers the expense associated with supporting new customers. Modernized systems also provide supply chain benefits by giving enterprises the flexibility to extend labeling capabilities to their business partners and by enhancing brand protection. Best of all, organizations can gain these cost savings and responsiveness benefits while improving label quality, not sacrificing it.

Enterprises are continually looking deeper into their operations and farther across their supply chains for opportunities to become more efficient. Often, they need to look no farther than their labeling processes for opportunities to improve responsiveness and reduce costs. This white paper will identify the hidden costs, inefficiencies, and risks resulting from legacy operations and explain why a modern label management platform is well suited to current enterprise needs.

To download the full white paper visit: http://www.nicelabel.com/white-papers/adopting-next-generation-labeling

Courtesy of NiceLabel, Inc

Click here for more articles about labels and labeling solutions