Top 7 Things to Consider when Implementing a Work-in-Process Tracking System

by Dr. Peter Green, Chief Technology Officer, BellHawk Systems Corporation

Are you managing one of the 80% of make-to-order manufacturers in the USA that are still using paper forms and Excel spreadsheets to track and manage their operations?

If so, you are probably finding, as many others have, that it is increasingly difficult to track and manage your operations using these old-fashioned methods. This is because we live in a 24x7, hyper-competitive, lean, global supply chain world in which customers expect rapid delivery of quality products at rock-bottom prices.

If you have been searching for a system to automate the real-time tracking, scheduling and planning of your operations, you have probably found a bewildering array of possible choices from low cost, smart phone Apps to expensive ERP systems.

This article suggests some questions to ask when comparing possible system solutions to address these issues. These are based on the practical experience of other make-to-order manufacturers and the system capabilities they have found valuable or even essential to the efficient running of their operations.

- Does the proposed system give you a real-time view of the status of your work-in-process? This requires capturing the status of customer orders in real-time as they flow from operation to operation. Using paper forms followed by manually keying the data into an Excel spreadsheet or ERP system does not give managers and supervisors the timely information they need to avoid bottlenecks and get customer orders out on time.

- Does the system give you a real-time view of the status of all the materials needed to make your products? This can includes tracking the status of:

- Available raw and intermediate materials, including project specific materials on order or in the process of being made

- Floor stock, including materials in KanBan bins

- The picking of parts from the stock room

- Work-in-process parts as they flow between operations, either as individually barcoded items or as parts in totes or on carts

- Parts waiting for test and inspection

- Finished parts ready for shipment, which may be in cartons, on pallets, in the finished goods warehouse, or staged on the shipping dock

- Picking, packing and shipment of finished products to customer site

A major issue for most make-to-order manufacturers is that they cannot keep track of all the materials for the customer orders flowing through their plant at the same time. This dynamic real-time tracking of materials in nested containers is very different from tracking inventory at static locations in a warehouse.

A major issue for most make-to-order manufacturers is that they cannot keep track of all the materials for the customer orders flowing through their plant at the same time. This dynamic real-time tracking of materials in nested containers is very different from tracking inventory at static locations in a warehouse.

- Does the system track the transformation of materials? This requires tracking which materials, by lot, serial number, and manufacturer, were consumed to make intermediate parts and then the conversion of these intermediate parts into finished goods. This is critical for capturing materials traceability data so that the source of defects can quickly be identified and the cost of recalls minimized.

- Does it also track the consumption of labor and equipment/machine time used in each transformation operation in making a product, including allocating these resources across multiple orders run at the same time on the same machine? This is essential to get detailed costs for each customer order, especially when many different parts have to be made, assembled, and shipped to the customer in multiple releases.

- Does the system support the ability to use a small number of “generic” part numbers for raw, intermediate and finished goods with different attributes, such as length, width, size, color, and other options? This avoids the problem of having to assign a separate part number to each different product you make for customers which, for some make-to-order manufacturers, could otherwise run into hundreds of thousands of different part numbers to maintain.

- Does it support the ability to track work-in-process materials and assemblies without assigning a separate part number to each intermediate product stage? For many make-to-order manufacturers tracking work-in-process materials is essential as they flow from one operation to another. But, at the same time, they do not want to create new part numbers for each intermediate stage in the process of making the material. Instead, they simply want to use the finished product part number and then flag the materials as work-in-process so they are not confused with finished product inventory.

- Does the system do real-time scheduling of jobs? Busy make-to-order shops have many customer orders flowing through their shops at the same time, which can present managers with a complex scheduling problem because some operations take less time than expected and others take longer. Trying to do this scheduling in real-time without assistance from your work-in-process tracking system can be challenging.

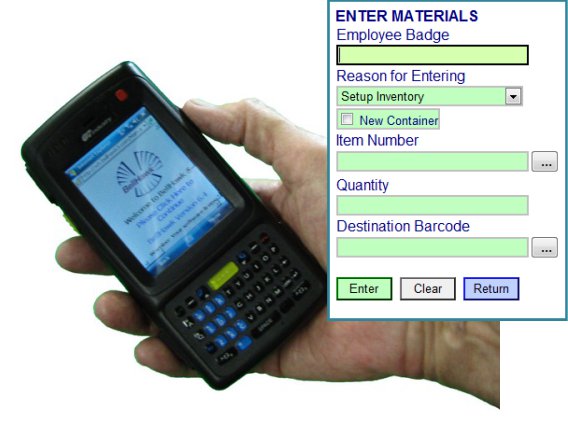

A key element to providing the above capabilities is automated data capture. This typically requires the use of mobile computers with integral barcode scanners and increasingly, the integration of RFID and other Internet of Things sensors, such as weighing scales.

In summary, effective work-in-process tracking systems must be able to easily handle the complexities of make-to-order manufacturing businesses. Most critically, these systems require the use of software such as BellHawk, that is able to capture work-in-process data in real-time at multiple geographic locations, analyze that data in real time using artificial intelligence methods, and present critical operational data to operations managers, supervisors, and customer support people in real-time, whenever and wherever it is needed.

---

About the Author

Dr. Peter Green is the Chief Technology Officer for BellHawk Systems Corporation (www.bellhawk.com). He has a BSEE and a Ph.D. in Computer Science from Leeds University in England. Prior to BellHawk Systems, Dr. Green was a Senior Member of the Research Staff at MIT and a full Professor at WPI. He is a current member of APICS and gives professional development talks about operations tracking.

Dr. Green has been implementing operations tracking and monitoring solutions for over twenty years. He is a domain expert in automated data collection as well as in materials tracking and traceability and automated planning and scheduling. His team at BellHawk Systems has implemented nearly 100 systems for clients including manufacturers, food and pharmaceutical processors, medical and biotechnology laboratories, as well as systems for the US Navy and Air Force and the Centers for Disease Control.

---

Other Barcode news of interest:

- Code Launches Customizable, Multi-Tiered Service Plans

- AIM Members...Join RAIN in Seattle!

- FoodLogiQ Recognized by Forbes Magazine for Innovation

- AIM Represents RFID Constituents at European Commission (EC) Event

- Ultracode Receives Global Recognition

- AB&R Celebrates Three Consecutive Years Being A Top Company To Work For

- PINC Named to Supply & Demand Chain Executive’s SDCE 100 Top Supply Chain Projects in 2017