Using Handheld RFID Readers to Manage Warehouse Inventory Efficiently

Handheld radio frequency identification (RFID) readers are an ideal way of keeping warehouse inventory up-to-date in a time-efficient, accurate and economical manner.

Handheld radio frequency identification (RFID) readers are an ideal way of keeping warehouse inventory up-to-date in a time-efficient, accurate and economical manner.

One of the main challenges of inventory systems is remaining constantly updated. Traditional barcoding systems cannot be speedily updated to reflect the current reality in a warehouse.

RFID, a system in which radio waves emitted from electronic tags are uniquely identified by readers, can provide the necessary accuracy. Any object in the warehouse with an RFID tag can be identified as a unique item and its location in the warehouse pinpointed.

What’s the best way to gather the information from these tags? Placing readers or beacons on every shelf is costly, and placing readers in every exit and entrance can be helpful if an item is transferred through that passage.

A handheld RFID reader, when integrated with a general RFID application system, combines the advantages of effortless mobility with RFID's unfaltering accuracy, drastically cutting the time of taking inventory and eliminating human errors.

Using a handheld reader, hundreds of unique RFID tags attached to inventory items can be read in a single swipe from several meters away. There is no need for a line of sight with an RFID reader, and objects do not need to be removed from their shelves. Using other systems, such as barcode reading, would necessitate removing the items from their cartons for individual readings in close proximity.

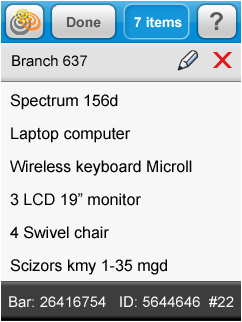

The handheld reader transfers the data to the RFID application system for analysis – but that’s not its only function. When the handheld RFID reader is fully integrated with the software application, it can also display the system data, providing dashboards with a constant real-time view of stock levels, incoming goods, order preparation, shipments and other typical warehouse activities. Goods can thus be monitored even from the early stages of ordering, through their warehousing and until their shipment to clients, thereby cutting down on human errors that undermine the efficiency of ERP systems in use.

Besides recording all the inventory items in their specific locations, uploading this information to the main inventory management system, and displaying  dashboards, handheld RFID readers can be used to:

dashboards, handheld RFID readers can be used to:

- Set off an alert if a product, defined to be located in a specific zone, is missing.

- Identify misplaced products.

- Search for an item in a specific zone, or entire warehouse. When the reader is directed at the item being searched for, an audio message can be played.

- Check stock for minimum and maximum levels, predefined in specific zones. An audio alert will be automatically sounded if a deviation from the set levels is detected, and the full details of the deviations can be displayed on the RFID handheld reader screen.

- Update a change in the location of an item, or note the completion of an order for shipment, and than synchronize with the main inventory management system.

Handheld RFID readers – a fast, inexpensive way to manage up-to-date inventory data in your warehouse.

(Images used with permission from Vizbee RFID Solutions: Top: Vizbee RFID Handheld Reader; Right: Screenshot of the Vizbee Inventory Management System (VIMS) software installed on the RFID Handheld Reader.)

***

Yedidia Blonder is the product manager of Vizbee RFID Solutions, an provider of RFID applications for inventory management, customized for multiple industries.

Related articles:

City Recycling Increases 260% due to RFID Tracking

Wash This: Washable RFID Technology for Hotel Linen and Uniform Tracking

RFID Tracking Prevents Patient Misidentification in Hospitals

Item-Level RFID: How Retailers Are Changing the Inventory Process

YouTube Video's that illustrate how to make labels and bar codes:

QR Code with a URL Web address

Create a QR Code for business cards

Make sheets of bar code labels

{jcomments on}